We Crave Carbon

We Crave Carbon was a short-term project that gave us invaluable experience. It showed us how to run an import/export business.

In 2018, a cycling enthusiast with a passion for both riding and competing in triathlons saw a unique business opportunity. After years of immersion in the cycling world, he identified a gap in the Brazilian market for high-quality carbon wheels for road bikes - an area dominated by only a few major players.

The Vision and Initial Steps

Driven by this insight, the founder embarked on an ambitious journey, researching suppliers, production technologies, product specifications, and taxation strategies. This project became a blend of two passions - cycling and entrepreneurship. The aim was to create a niche brand, rooted in mission, vision, and values, tailored to a specific consumer profile.

Challenges and Lessons Learned

Although the business didn’t extend beyond the first import batch, the experience was invaluable. We conducted extensive user research, gathering insights through surveys, interviews, and even casual conversations while riding a bike. We analyzed competitors, supply chains, and business models, gaining crucial knowledge in the process.

Brand Development and Visual Identity

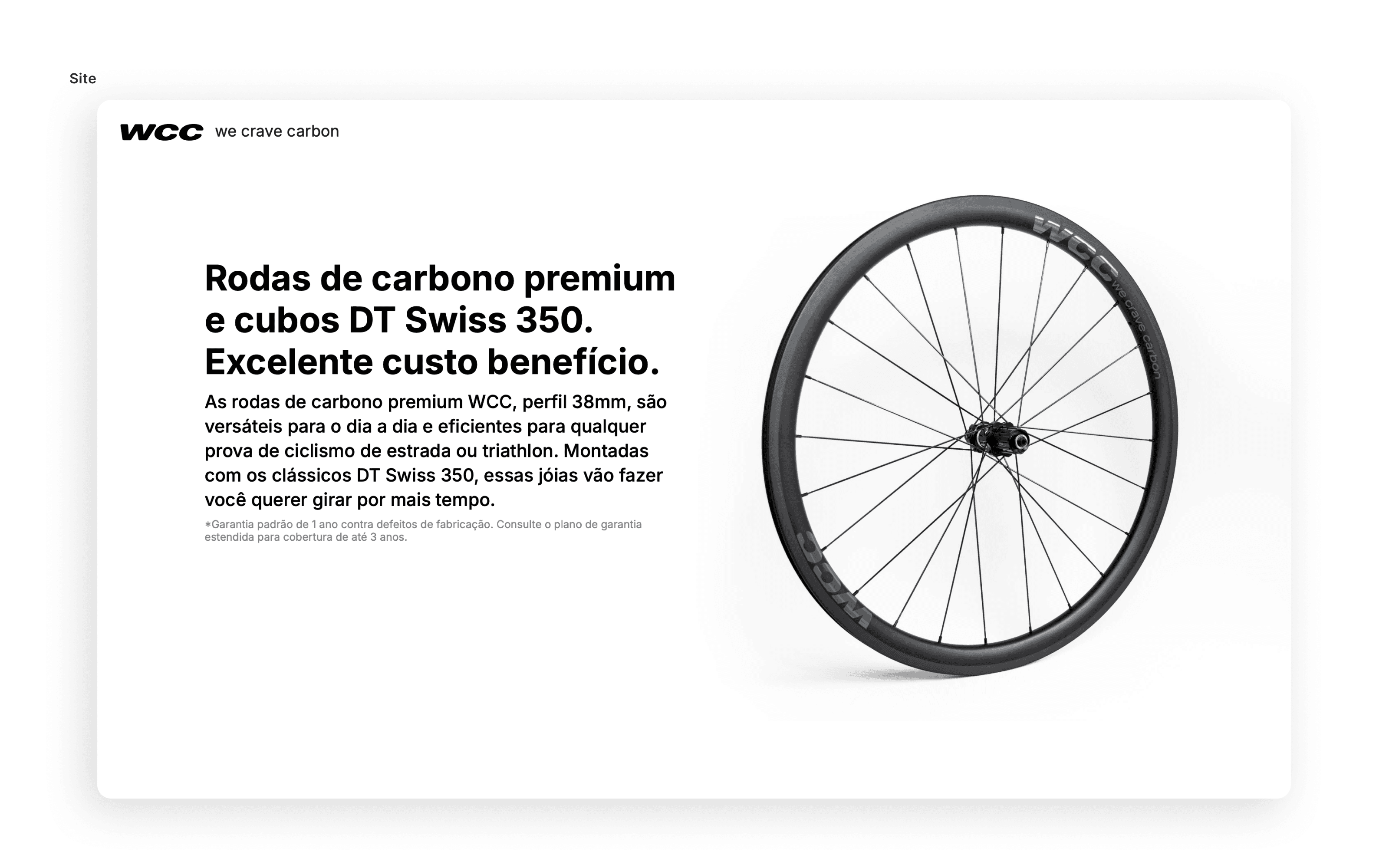

The development of the brand’s visual identity was a highlight of the project. With years of expertise in graphic design and branding, this phase allowed us to channel our creative skills, crafting elements that resonated with the niche market.

While the business may not have reached its full potential, the lessons learned in this venture sharpened our expertise, contributing to the future success of other projects in design and entrepreneurship.

The product itself

The customization and product photography were handled with meticulous attention to detail. The goal was to ensure that, despite being new to the market, the brand projected trust and high quality right from the start. At the time (pre-disc brake era, around mid-2018), carbon wheels were often questioned due to the risk of overheating at the braking surface. This friction point, where the brake pads make contact, generated high temperatures that could lead to resin melting and product deformation in lower-quality wheels - a serious safety concern.

These wheels, however, were different. After three years of rigorous personal testing in various weather conditions, training consistently, and competing in both national and international events, they proved to be a perfect combination of efficiency and durability.

Visit landing page here

Final thought

Unfortunately, good design alone doesn't sustain a good business. A network of intelligence and skills is necessary - that’s a fact. At the time, some partners had to step away from the operation. It was impossible to continue. We're happy with what we accomplished. We're proud to have created a brand that represented everything it needed to represent, caught attention wherever it went, and still holds up, with visual appeal and aesthetics that work even 8+ years later.

This is our greatest goal as a design studio: to deliver brand value and ensure that our clients’ investments stand the test of time.